OUR MINING EXPERIENCE SINCE 1863

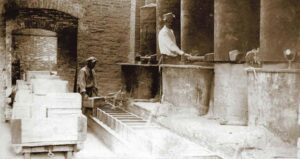

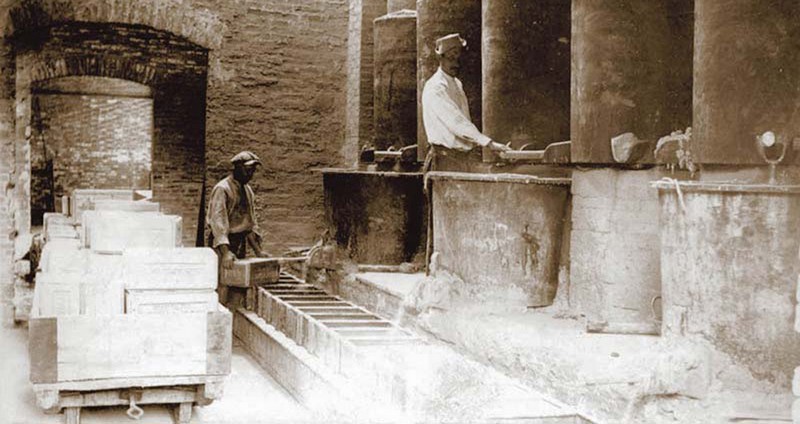

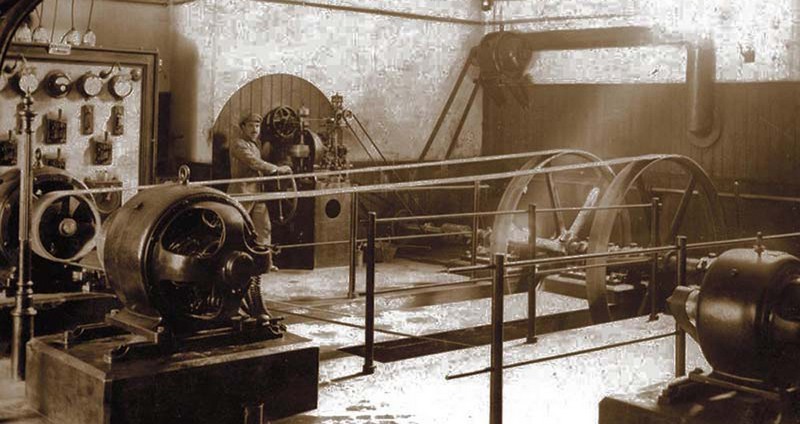

A long tradition of extracting, refining and grinding sulphur from the subsoil of our factory.

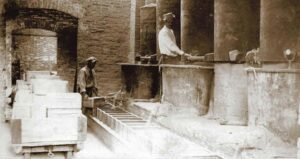

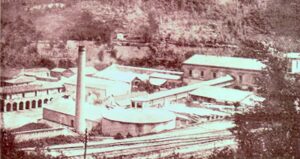

FROM INDUSTRIAL VILLAGE TO MODERN ESTABLISHMENT

Once upon a time, the mining industry needed large spaces for processing and for around a thousand employees. Today, in the active part of the factory, two efficient facilities produce and bag, while the structures and machinery that for a long time allowed S.A.I.M. to contribute to the development of Italian agriculture, industry and handicrafts, survive as a heritage of industrial archaeology.

1863

In 1863, Ferdinando Capone of Altavilla Irpina, land owner in Bosco della Palata, near a bend of the Sabato river, learnt that the local farmers, while burning the brushwood, sometimes saw flames and smelled a strong odor. It took only a few blows with a shovel to discover the first sulphur-bearing strand and to begin, with the few farmers available, the extraction of the sulphur-rich soil, high in demand as fertiliser.

Three years after the start of sulphur extraction and commercialisation, the Directorate of the Faculty of Italian Chemistry and the Agricultural Consortium of Avellino commissioned engineer Primo Lattanzi to carry out some research in the Altavilla Irpina area. It was 1866 and the news of sulphurous deposits in the area was soon confirmed. Research was also subsequently undertaken by the Di Marzo family, originally from the Vesuvian area, as evidenced by the volcanic stone triumphal arch in the centre of the building of their tuff factory.

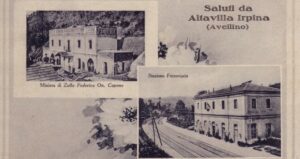

Thanks to the entrepreneurial initiative of the young Federico Capone, who succeeded his father in the leadership of the family mine, in 1878 the mines, which had sprung up one after the other since the discovery of the deposit, formed a consortium and the group of quarries and factories was called the Miniera Sociale (Social Mine).

The increase in mining activity triggered a process of overall development of the area that involved roads, construction and transport. From 1891, the railway, strongly desired by Federico Capone, replaced river transport by barge, which suffered from the problem of humidity, harmful to ventilated sulphur. The train was widely used by workers to reach the mines, but above all it was used to market sulphur sacks and acquire raw materials such as coal, needed for the boilers of the growing industrial facility.

1868

1906

In 1906, at the agricultural exhibition in Salerno, Altavilla Irpina sulphur won the grand prize and gold medal. Meanwhile, one of the first mines, “La Vittoria”, was exhausted, but soon a new one was opened not far away, later named “F. Capone”.

The Altavilla Irpina plant gradually expanded, involving the area pertaining to the Molino Pannone, on the opposite side of the river. This mill was used to grind the mineral, on behalf of the Società Miniere Sulfuree di Altavilla Irpina (Sulphurous Mines Company of Altavilla Irpina), in order to create an anti-cryptogamic, which is still in great demand in viticulture as it’s an excellent remedy against powdery mildew.

In 1919, the Società Miniere Sulfuree and the Molino Pannone merged into the Società Anonima Industrie Meridionali (S.A.I.M.). The sulphur extracted at this time covered about 3% of the world’s needs and the company began a period of great splendour.

Mining activity was then drastically reduced, until the final closure of the S.A.I.M. mines in 1983, by Ministerial Decree. Since then, the premises has continued to process sulphur from the already pure Italian refineries. Today, sulphur is in fact extracted from fossil substances (hydrocarbons), maintaining its natural origin from the subsoil and with a much higher purity than the one extracted from rocks.

Post Second World War

Today’s agriculture requires high quality standards and our mission is to guarantee the excellent level achieved by our powdered sulphur products, but also to offer an increasingly wide range of products for organic farming, from fertilisation to pest control. Browse the catalogue or discover our products on the dedicated page!